A Complete Guide to Φ42 Steel Pipes

- sattheplocthien

- 24 thg 11, 2025

- 3 phút đọc

1. General Introduction to Φ42 Steel Pipes

A Φ42 steel pipe—also called D42—refers to a steel tube with an outer diameter of 42 millimeters. In engineering terminology, the symbol “Φ” indicates diameter, so “Φ42” simply means a pipe whose outside diameter is 42mm.

These pipes are widely used in construction, mechanical engineering, water systems, and structural frameworks because of their durability, strength, and ease of fabrication.

Common production standards include JIS (Japan), ASTM (USA), BS (UK), and TCVN (Vietnam), ensuring consistent quality and dimensional precision.

2. Classification of Φ42 Steel Pipes

2.1. Classification by Surface Type

Black Steel Φ42 PipeThis type has a natural dark metallic surface without any protective coating. It is known for high strength and is typically used for structural applications, mechanical fabrication, scaffolding, and industrial frames.

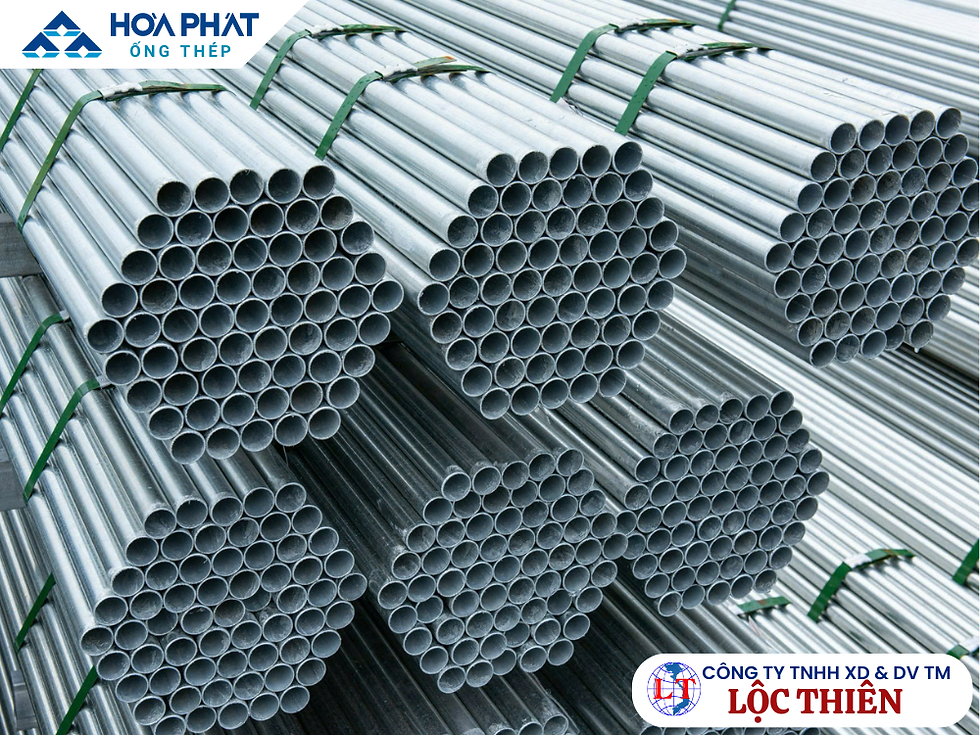

Galvanized Steel Φ42 PipeThese pipes are coated with a layer of zinc to prevent corrosion. Galvanized pipes are suitable for environments exposed to moisture or chemicals and are commonly used in water lines, outdoor structures, and long-term installations.

2.2. Classification by Usage

Pipes for Water or Gas DistributionΦ42 pipes can be used for transporting water, compressed air, and certain gases depending on the pressure and wall thickness.

Pipes for Mechanical EngineeringThey are widely used in creating machine frames, fabricated parts, agricultural machinery, and production lines.

Pipes for Structural ConstructionΦ42 pipes are essential in steel frames, trusses, pre-engineered buildings, and scaffolding systems.

Pipes for Interior and Decorative PurposesBecause they are easy to bend, cut, and weld, Φ42 pipes are used for handrails, railings, furniture frames, and decorative steel structures.

3. Technical Specifications of Φ42 Steel Pipes

The outer diameter of the pipe is fixed at 42mm. Wall thickness usually ranges from 1.2mm up to 5.0mm, depending on the required strength and application. Most pipes are manufactured in a standard length of 6 meters per piece.

The weight of a Φ42 pipe increases as the wall becomes thicker. For example, a pipe with 1.2mm thickness is lightweight and suitable for light-duty applications, while a pipe with 5.0mm thickness is much heavier and used for heavy structural loads.

Technical tolerances—such as ovality, straightness, and wall thickness variation—follow industry standards like JIS, ASTM, BS, or TCVN. These standards ensure that the pipe meets safety and performance requirements during installation and use.

4. Outstanding Advantages of Φ42 Steel Pipes

High Strength and Tensile DurabilityΦ42 pipes are designed to handle high mechanical stress, making them reliable for load-bearing structures.

Excellent Load-Carrying CapacityThanks to their uniform diameter and appropriate wall thickness, these pipes can support heavy weights and resist deformation.

Corrosion Resistance (for Galvanized Types)Galvanized Φ42 pipes resist rust and environmental corrosion, extending service life in outdoor or humid environments.

Easy to Process and WeldThe pipe material allows cutting, bending, drilling, and welding with minimal difficulty, supporting efficient fabrication.

Versatile ApplicationsFrom construction to mechanical engineering, Φ42 steel pipes adapt to many different project requirements.

5. Common Applications of Φ42 Steel Pipes

Φ42 pipes are used in a wide variety of construction and industrial activities:

Residential and commercial building construction

Steel structures, trusses, frames, and pre-engineered buildings

Water supply systems, compressed air lines, and fire protection systems

Railings, handrails, workshop frames, and factory structures

Temporary foundations, scaffolding, and support poles

Mechanical manufacturing and industrial production

Their combination of strength, flexibility, and durability makes them one of the most popular pipe sizes in practical engineering.

6. How to Choose High-Quality Φ42 Steel Pipes

Inspect the Surface, Weld Seam, and ThicknessCheck for smooth surfaces, straight uniform welds, and accurate thickness according to the required specifications.

Verify Labels, Batch Codes, and CO/CQ CertificatesA reliable manufacturer always provides clear identification marks and official quality certificates.

Differentiate Standard vs. Recycled SteelStandard pipes have consistent color, strong welds, and precise dimensions. Recycled or low-quality pipes often have uneven surfaces, weak weld seams, and noticeable deformation.

Choose the Right Thickness for Each Purpose

1.2–1.8mm: light-duty frames, furniture

2.0–3.0mm: general construction, water lines

3.5–5.0mm: heavy-duty structures, industrial load-bearing applications

Lộc Thiên Steel Contact Information

Address: No. 1001, Group 22, KP1, Long Hưng Ward, Biên Hòa City, Đồng Nai

Fanpage: facebook.com/sattheplocthien

Hotline: 0858 676 679

Zalo Business: https://zalo.me/sattheplocthien

Website: https://sattheplocthien.com/

Bình luận